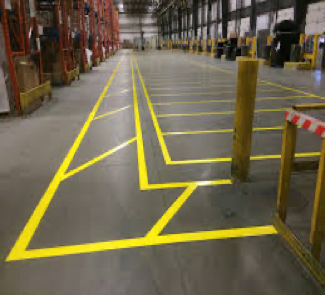

WAREHOUSE STRIPING AND SIGNAGE

McCord Contractors Inc. can offer suggestions on how to help you and your facility stay safe.

Do you want high-quality floor striping that are compliant with OSHA guidelines? Do you need to remove poorly-installed floor striping and install new ones? Do you want to modify your current floor layout? Whatever floor striping service you need, look no further! Our professional team is trained and insured to provide OSHA warehouse striping in any facility.

Why do you need professional warehouse striping and signage services?

- Properly-installed warehouse striping and signage helps protect your employees from potential accidents and injury and helps lower safety risks.

- OSHA-compliant floor striping keeps your facility well-organized

- High-quality warehouse floor striping installed by our team of experts give your facility a professional aesthetic

- OSHA floor striping in your warehouse can increase your productivity by up to 30%

OSHA Floor Striping Guidelines

The Occupational Safety and Health Administration (OSHA) provide guidelines on how organizations can help improve the health and safety in warehouse and distribution centers. Warehouse floor striping allows companies to mark and identify aisles and passageways to be kept clear for safe operational workings and in the event of an emergency.

OSHA sets out in its publication, Material Handling and Storage, the following:

What About Aisles and Passageways?

When using aisles and passageways to move materials mechanically, workers must allow sufficient clearance for aisles at loading docks, through doorways, wherever turns must be made, and in other parts of the workplace. Providing sufficient clearance for mechanically-moved materials will prevent workers from being pinned between the equipment and fixtures in the workplace, such as walls, racks, posts, or other machines. Sufficient clearance also will prevent the load from striking an obstruction and falling on an employee.

Employers must ensure that all passageways that workers use remain clear of obstructions and tripping hazards. Workers should not store materials in excess of supplies needed for immediate operations in aisles or passageways, and employers must mark permanent aisles and passageways appropriately.

Please Take Note:

given work place liability, safety of our workers and those within close proximity to the process as well as inconsistent results, we no longer acid etch or advocate its use as a surface preparation method for concrete flooring to receive a resinous system. In order to produce the correct surface profile for the greatest adhesion we use steel shot blasting equipment, both portable and electric depending on what the work environment dictates, as well as planetary diamond grinding equipment for the purpose of readying the concrete for its respective resinous system. Using diamond tooling, our grinding process can be used to remove coatings (aggressive diamonds) or grind existing concrete (medium to coarse diamonds to produce an anchor profile). For the purpose of polishing concrete we can also use finer diamonds to create a honed or highly polished look. We also grind existing paint to ready a surface for new coating.